Pin Marking

Today's manufacturing and customer demands requires the need for the permanent marking. Whether it is a serial number, part number, 2D data matrix code, QR code, logo or other product information, the codes should be impossible to remove, whether deliberately or accidently through use. These codes can be required by law, safety regulations, or product traceability of the manufacturer and even accreditation. Sometimes, it can just make good business sense to have parts clearly, professionally and permanently marked for integrity.

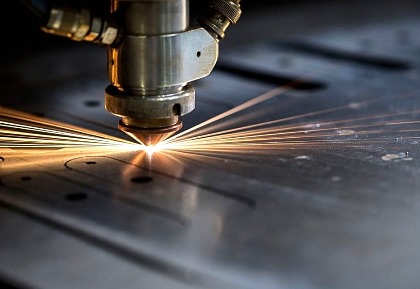

Laser Marking

Laser marking leaves extremely precise, accurate and high-quality marks that are easily readable by the human eye and by machines too. These marks are durable and can be easily traced. It is a process that works extremely well with a range of materials. Since there is no consumables to deal with, production uptime can be maximized and reduces maintenance costs, along with obtaining a high quality code. Depending on the type of laser used, lasers can work with materials such as metals, glass, plastics, paper & plastics.

Applicator

With the constant challenge to save manpower costs, time, and label placement accuracy of manually applying labels, companies have the choice of using our range of semi-automatic to fully automatic Label Applicators, which can be integrated inline or offline. Our range of applicators works with a variety of pre-printed pressure-sensitive labels to be applied onto your products. From table top to fully automatic, systems, get the accuracy and label placement that makes your product stand out.

Print & Apply

Print & Apply labeling systems combine label printing and a label dispenser into a single unit. Our range of Print & Apply systems will automatically print and apply labels to your products, cartons or pallets in one single process and a choice of 6 different locations for labels onto cartons. With our versatile connectivity, be it via PLC's or LAN connections, the Print & Apply units can receive the information to be printed on the fly. Since every client's production requirement is different, our Print & Apply solutions have the possibilty to interchange applicator arms that will completely offer a new solution without having to purchase a new Print & Apply system. Our solution ensures that every label goes onto the right product, carton and pallet correctly, every time. You can provide assurance to your supply chain partners by empowering them with correct information to speed up the delivery process.

Data Capture

Not only do we help clients mark their products, our range of handheld to fixed scan barcode checking systems and vision inspection systems helpts to ensure that you have everything you need to inspect, check or reject during the data collection process. Our 1D and 2D barcode scanners, and vision scanners will to check to validate missing prints, missing labels or caps, label orientation or label positions, in different environments from low to high production speeds. With real time processing, your production process can identify challenges faster with minimum waste.

Find Out More About Data Capture!

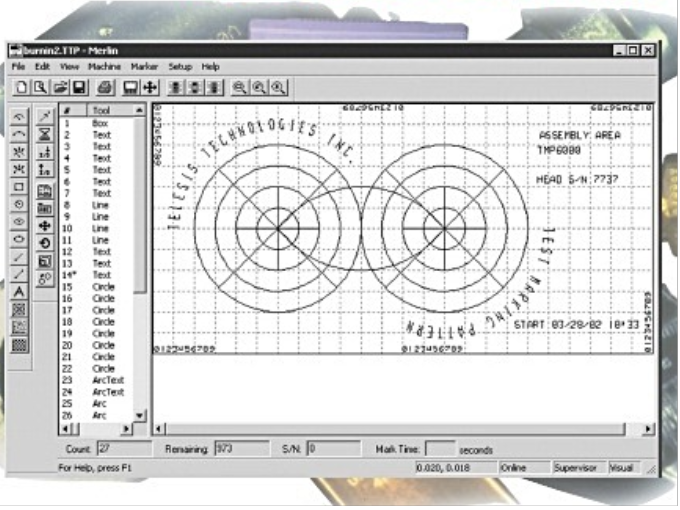

Software

Recognizing the need for different 3rd party devices to communicate with one another, or having to communicate with multiple marking units on the production flow or just managing updating settings from one location, the demand for customized software to manage all these interactions on one platform is available. With our software team, we are able to link information, enable changes, monitor through audit trails, provide timely reports at all levels from the Production floor, to Operations and even to Marketing teams ensures that communications can run seamlessly.