If you manufacture aerospace components, chances are you're expected to see very clearly mark to precise specifications for traceability.

Permanent, durable markings are of the utmost importance when it comes to traceability in the aerospace industry. From an airplane’s wings down to its smallest, most intricate components, every material and component manufactured for flying an aircraft can be tracked and traced with a laser or dot peen marker.

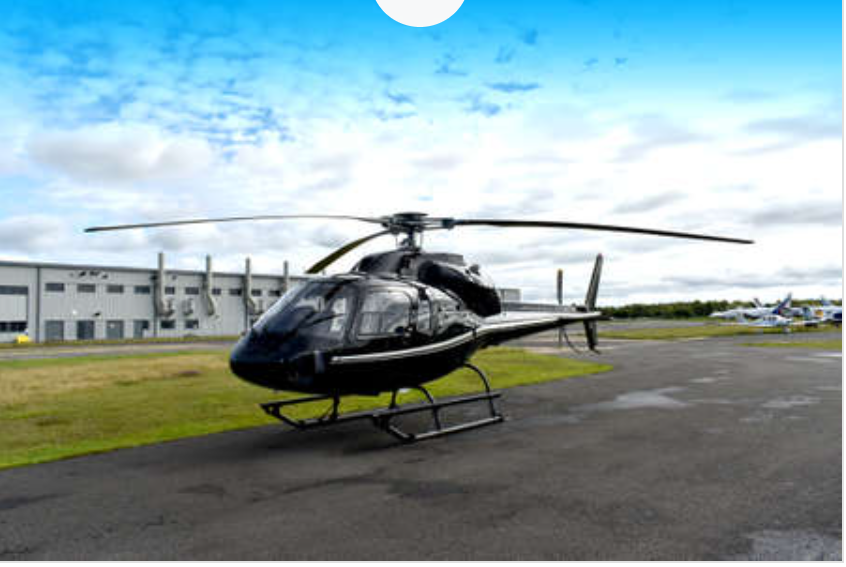

In a high-heat environment like that of a plane engine, temporary markings just won’t work. You can’t rely on traditional marking methods like inkjet, labeling, and RFID. What’s a valuable solution that works long-term on jets, defense aircraft, satellite, rocket engines, and more? Clear, permanent marks made by lasers or dot peen marker.

Many aerospace manufacturers – including Rolls-Royce, GE, Pratt & Whitney, Boeing and Airbus – have their own individual marking standards. Whether you require dot peen or laser, we can help you choose the best marking solution for the component type, volume and standards you need to accommodate.

Common aerospace component marking applications:

- Jet engine and airframe components

- Landing gear

- Data plates, nameplates and tags

- Helicopter, airplane and other aircraft components